this post was submitted on 02 Sep 2024

36 points (100.0% liked)

diy

22031 readers

1 users here now

Finally, a comm for that one user who hand-makes longbows. This ones for you, comrade.

founded 4 years ago

MODERATORS

you are viewing a single comment's thread

view the rest of the comments

view the rest of the comments

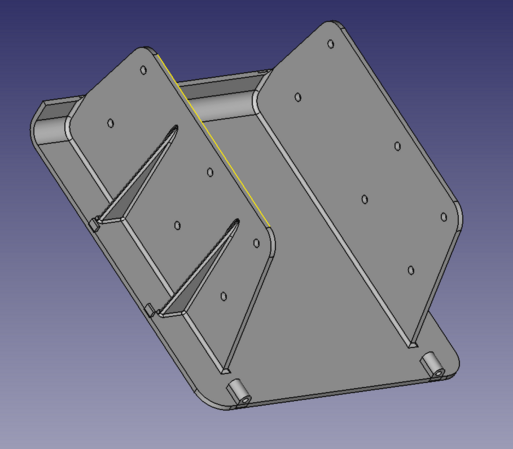

You can grab the file here: https://matapacos.dog/stuff/h5_drive_rack3.FCStd

This part was designed for the NZXT H5 Flow PC case. I used vanilla FreeCAD 0.21.2 (built from source on Gentoo though). I did everything using a single solid in the PartDesign workbench. Overall, the model isn't a testament to great design, but I used datum planes as references for a lot of important bits which helps keep things a little bit more stable. I barely named any of the features though and the fillets, as always, are a crapshoot. I tried to apply them to the most structurally useful intersections and stopped when I began facing diminishing returns.

The model only tells half of the story though. There are a lot of random dimensions shoved in there, taken either by reverse-engineering the original part with a set of calipers, or by looking up prints for SATA hard drive screw locations, which are not annotated whatsoever in the model (I don't know if there is a way to do this, but it would be really useful, like adding comments to a piece of code). When you see odd random numbers thrown around, assume it was some inch measurement, plus the high limit tolerance, then converted into millimeters. Some of these measurements aren't in obvious places like a sketch, but can be found in the offsets of various pad operations, datum plane locations, or linear pattern operations. Other dimensions (particularly, internal diameters) are fudged and over-sized due to the tendency of these features to shrink by 0.2-0.4mm in the FDM 3D printing process.

Oh yeah. I love doing that. Earlier when I was grumbling about annotations, at least in the spreadsheets you can write a couple sentences about what a variable does. If I'm "engineering" something from scratch, I'll typically put important dimensions and clearances in a spreadsheet and reference them within sketches. You need to be extra diligent when designing your model that it will successfully recompute given a range of values though. In the case of reverse-engineering, like this model, you throw design intent out the window and just pray everything fits.

Datum planes (as well as datum axes and points) are VERY useful. They are defined independently of any geometry in the model, and form a solid foundation to build other features from (i.e. a plane to sketch on, or an axis to bore a hole through or revolve around). You can also reference them in sketches just like any other part geometry, but they will ALWAYS be there when you change a dimension and recompute, unlike an arbitrary edge or vertex of a body. They are the canonical method to avoid the "topological naming problem." Even in commercial CAD systems like Creo Parametric or SolidWorks, which are somewhat smarter than FreeCAD about recomputing your model after changes, you WILL have problems if you're building a house of cards out of ephemeral geometry references on top of ephemeral geometry references.

Probably the most useful case for a datum plane, aside from a surface to sketch on, is a reference to perform a mirror operation. If you need to mirror a feature across a plane which isn't your base XY/YZ/XZ plane, you create a datum plane and mirror across that. Same goes for a datum axis. If you need to do a revolve operation or a radial pattern around an arbitrary axis other than X, Y, or Z, you create a datum axis and use that. These datums can also be referenced during a pad/pocket operation, where instead of specifying a dimension, you can tell the operation to pad/pocket until it hits a plane (which can be arbitrary and does not need to be parallel to the plane you are padding/pocketing from).

I've never used a multi-transform before, but all it does is combine several mirror/radial pattern/linear pattern operations into one operation. I do this to mirror features like the triangular ribs, then duplicate them at a linear offset. All a linear pattern does is duplicate geometry and translate it along an axis (i.e. turn one hole into a line of three holes). Apparently FreeCAD does not allow you to do a linear pattern of a mirror, or a mirror of a linear pattern, so these two operations need to be combined. I feel like I didn't run into this problem when I was using the RealThunder fork.

Let's not get carried away now. The computer will always find a new way to misinterpret your intent. CAD systems are like a geometric monkey's paw. :)

Anything that has vertex ordering can end up burning you. I deal with polyline geometries at work a lot and doing merge and explode operations can result in visually normal geometry with absolutely cracked vertex ordering depending on the order of the input lines.

Love to fillet two edges together and have an artifact 500 vertexes away because that's how the parts were stored internally.

Check this tutorial out if you haven't

It's using Link Branch (now officially endorsed) and is a few years old, but it goes through basically every tool in part design

It's well maintained and I've had no issues with it. There's also the Ondsel branch thats based more on LinkStage and kind of an intermediate between LinkStage and FreeCAD main.

I'd definitely try Ondsel if you haven't been able to get LinkStage working, it's definitely worth it and it's got a moderate solution to the topological naming problem as well as a much more intuitive part system. Like you can extrude and pocket faces directly.

Here's a blog post about it

They don't want to adopt them because it's a breaking change as it is. The project files that were made before the patch are not fully compatible out of the box with the patch without a way to migrate them.

FreeCAD has a very X11 style development strategy of "don't ever break backwards compatibility". Ondsel is actually working directly with the FreeCAD team to bring these patches into main within the year so you can always wait. There's going to be a feature freeze until the topo issue is solved (merging Realthunder's fixes into main) then they'll release v1.0 and re-open feature development.

It was a manpower and feature creep issue. The merge would take months, it would conflict with tons of existing and in development PRs, and would require a whole new set of unit tests.

FreeCAD until recently didn't have any full time developers, so executing a merge like that would have been very difficult as the longer you spend on it, the more out of sync it becomes with the main branch and the more work you have to do to bring it back in sync.

Again, those blog posts on Ondsel or the Issues page/forum for FreeCAD have more information if you feel like looking, but it's all a very interesting story and I'm glad that it seems to finally be resolved.

Upstream is adopting many of these changes. A 1.0 release candidate fully integrating the toponaming changes from RealThunder's branch is supposed to be released within a week or two. There are many other convenience features in the RT branch (like better section views, live updates to chamfer/fillets, non-contiguous bodies, etc) but backwards compatibility with existing models is much more important in upstream than it is in experimental forks like RealThunder's. Basically, it just takes time.

I found a YouTube link in your comment. Here are links to the same video on alternative frontends that protect your privacy: